JSC Slutsk Sugar Plant

223610, Slutsk, 6 Golovashenko Street

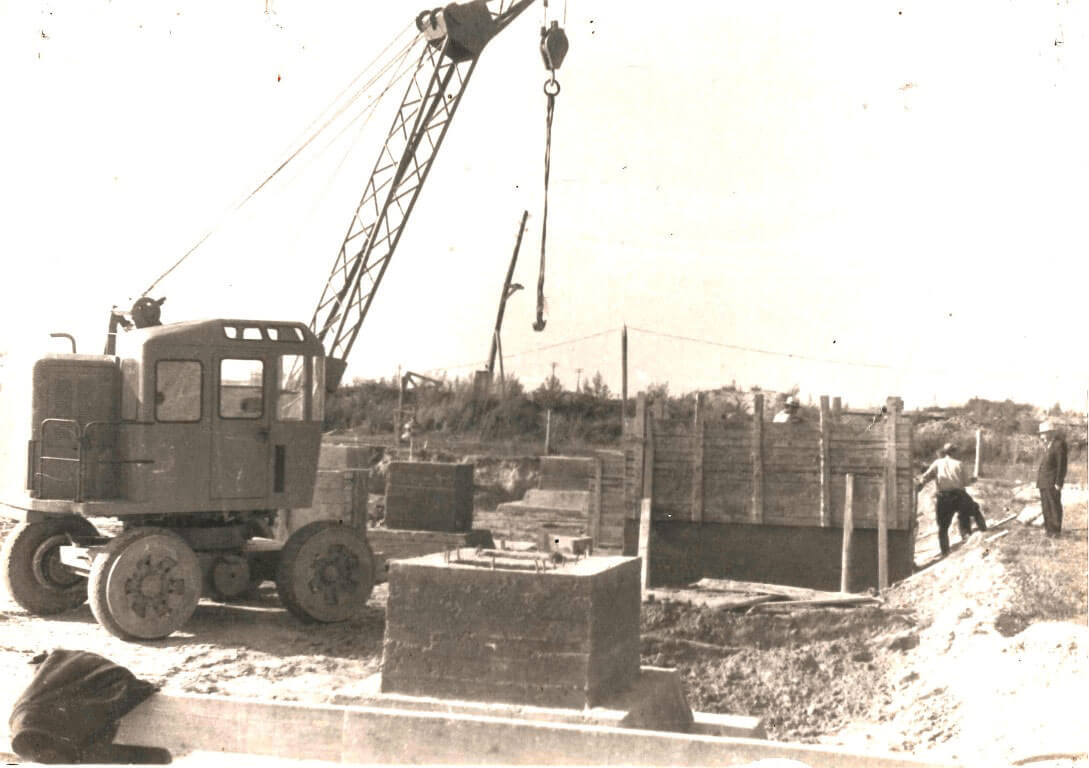

The Council of Ministers of BSSR had decided to build a sugar plant in Slutsk with a capacity of 3 thousand tons of sugar beet per day.

In 1965 the first sugar was produced in the Slutsk Sugar Plant.

By the order of the Minister of Food Industry of BSSR of April 6, 1976, the Slutsk Sugar Plant was reorganized into the Slutsk Sugar Refinery.

In the process of privatization of state property "Slutsk Sugar Refinery" was transformed into an open joint stock company by the order of MRSP #62 dated December 30, 1996, issued by the Minsk Regional Executive Committee.

There are five raw pulp presses, manufactured by Italian company Babbini, launched in production process, purchased in phases within 2006-2016 as the plant's production capacity increased.

A drying and pelletizing workshop was built. Dried granulated beet pulp is the most valuable additive for livestock feed. Production of raw pulp rolls, wrapped in a stretch film of 1300 kilograms was organized. The film enables to keep the product fresh for a long time.

German made centrifuges were installed in a product workshop in addition to the existing centrifuges, mounted and put into operation: a second sugar dryer, a new station for the recrystallization of second carbonation juice, gravity clarifiers of the first carbonation juice.

A new turbine-generator set with a capacity of 7.5 MW was installed at the CHPP of the plant. The plant is fully self-sufficient in electricity and a part of it (about 1 MW) is supplied to the overall power system. Consumption of fuel and energy resources over the past years has decreased by half.

A complete modernization of the thermal scheme of the plant was completed with the installation of three new evaporators for surface heating of each 5,000 square meters, produced in Poland and 12 plate type heaters of the German company GEA, which allowed to reduce the consumption of thermal energy by half. Annual savings amounted to two or three million dollars.

An extraction tower produced by a German company BMA with a production capacity of 10,000 tons of sugar beet processing per day was installed.

A new packaging factory with three automatic lines was put into operation. The lines are fully automated and controlled by one operator. The machines form packages from a roll of paper, dispense and pour the product. Even faulty packages are rejected automatically.

Two saturators were replaced by more efficient and productive ones.

Two gravity clarifiers of diffusion juice were installed.

A machine for wrapping a raw beet pulp in rolls, produced by Flexus, was purchased and installed.

Three boilers of CHPP were automated.

To ensure full capacity utilization of the extraction tower, two Ukrainian sugar beets slicers were replaced by more powerful German types TSM 2200-22-600-SAC, and the volumes of beet silos were increased in front of sugar beet slicers as well.

The fifth vertical crystallizer of the third product was purchased and installed, equal in volume to the four existing ones.

The construction of two containers for storage of sugar beet syrup, 40 thousand tons each, is being completed. Height and diameter - under forty meters! Two such storage facilities enable to process about 45 thousand tons of sugar. Syrup processing allows to refuse of import of raw sugar cane and switch to the production exclusively from sugar beets.

Was built a beet-washing complex, which, taking into account the construction of syrup containers, could increase the daily processing of beets to 12,000 tons without reconstructing the sugar house.